Condensate Drain Traps

Liquid float drain traps

Call us at 908.362.9981 to speak with a sales engineer

Automatic

float style condensate traps provide a reliable method of

automatically draining liquid from a pipe system without loss of

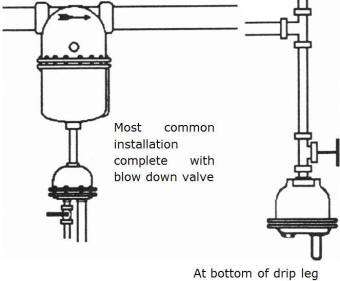

any process gas. Float drain traps are typically installed

at low points in the plumbing system where liquid accumulates

from storage tanks, gas/liquid separators and at the bottom of

vertical piping.

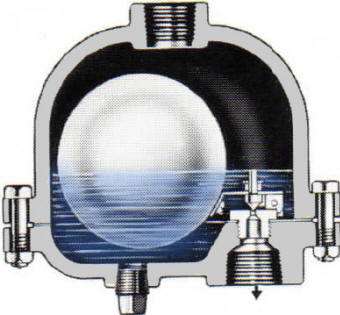

How Float Drain Traps Work

Liquid flows into the drain trap from

above and fills the trap until the hollow stainless steel ball

floats sufficiently high enough to open the valve attached to

it. The system pressure acts upon the liquid and it passes through

the valve to drain until the level within the trap drops

sufficiently, causing the float to drop low enough to seal the

drain orifice closed. A

detailed article illustrating this style of drain trap, installation

guidelines, maintenance and troubleshooting can be viewed online

"Float drain traps, how they work, applications and maintenance"

(PDF).

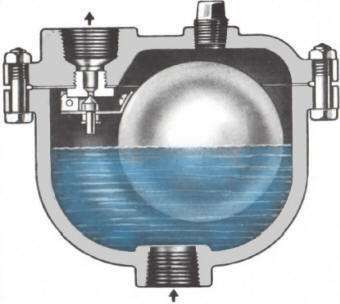

Inside of a typical float style drain trap

| Lower half of model 90/95-AC trap with float attached. | Float extended to reveal valve orifice | Close-up view of valve plunger and seat |

|

|

|

|

At all times there is a barrier of

liquid within the trap, thus only the liquid drains from the

trap and the steam, compressed air or other inert gas stays

within the piping system. The lower plug is used for

occasional blow down if particulate such as pipe scale are

introduced into the trap. Installing a Y strainer to

protect the trap from excessive scale found in older systems is

a good idea. All of the serviceable components are

attached to the drain trap cover for easy inspection and

maintenance.

When installed in locations susceptible to

freezing, we offer models that have an extra port in which a 50 watt

heater can be installed; this keeps the trap reservoir from freezing.

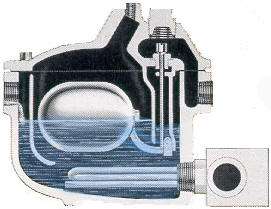

Air Vent Trap

Air Vent Trap

Some of our float drain traps can be used as a vent trap. Whereas float drain traps are used in low sections of piping to drain-out accumulated liquid, you can invert some drain traps and install within high sections of piping to eliminate accumulated air/steam/gas. The process is simply reverse; gravity ensures the discharge vavle is open when not filled with liquid, thus allowing trapped gas to vent. Once liquid sufficiently floats the ball, the valve orifice is closed. These are commonly installed on high capacity water pump systems to assist with venting air entrapped within the pump head and piping during start-up priming.

Capacity Chart

The following chart provides the estimated flow rates for a given orifice size at various pressures. It is accepted practice to incorporate a 3:1 safety factor when selecting your drain orifice size; thus if your expected liquid load is 50 lbs/hr, use an orifice which can handle up to 150 lbs/hr. If your expected liquid load is > than the flow rates below, or if your differential pressures are higher, contact us for information on additional designs.

You can calculate the approximate flow rate for other pressures using the formula provided where:

Q1 and P1 are the known flow rate and pressure

Q2 is the resulting flow rate for the desired pressure P2

DOCUMENTATION

-

Outline Drawing: Cast Iron model 90-AC

-

(note: side inlet version was discontinued, see alternate: Type S trap for a side inlet version equivalent to the 90-AC)

-

-

Installation, operation and maintenance manual for type 90 & 95 flat drain traps